when i got my car, the 2 special mounting nuts were missing and the panel was warped from being off so long. i bought 2 new nuts from fords for some silly price and they didnt hold at all onto the taillight stud. the sloppy panel really bothered me.( one of those little things that drive you nuts!!) so i modified fords nuts to work like they should. some guys have installed washers on the ones that do grab, because they bottom out before they snug up the panel but i fixed that too. it worked great and looks factory.

1) clamped the plastic nut in a vice and cut off 5/16" with a hacksaw

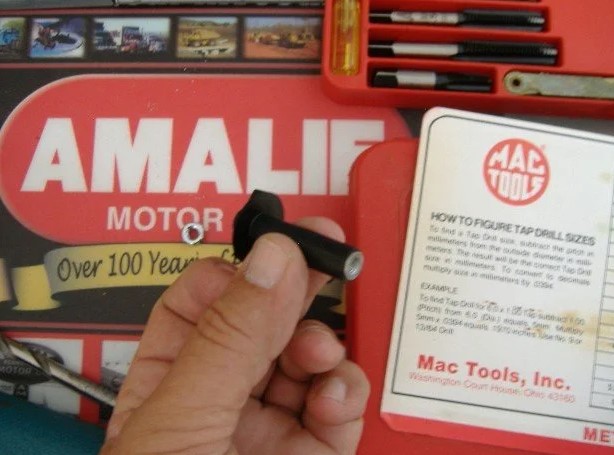

2) cleaned it up on the grinder and reamed it by hand w/5/16" drillbit

3) used 2 alum inserts from 2216 aluminum arrow shafts( archery)

4) drill the insert with 5mm(or #9) drillbit and tapped with 6mmx1.00

5) pressed the insert into the plastic nut in vice( could use some epoxy, but the insert fit great)

6) put a little anti-seiz on the stud and screwed them on

Story’s Author

United States of America, Traverse City

United States of America, Traverse City