My first black V8 SRX that the wife totaled had the chrome in the interior headlight painted body color and it looked bad ass.

This time, I am gonna (I think) leave the chrome reflectors, but add some sequential switchback LED light pipes, and perhaps some LED strobes.

Here goes nothing... cant wait to share the progress w you guys.

Step 1. Remove everything from the headlamp module. That means all bulbs and all wiring. You will find one of the rubber wire junction pieces is quite difficult to route and remove, but use care and you'll eventually be able to squeeze it through small passage areas to completely remove the entire wiring harness. Once headlight is bare of all wiring, and anything you can remove, next step.

Step 2. Bake headlight in your wife's oven when she is not in the house or watching TV upstairs. This part is key. Definitely do it stealthy-like. Happy wife happy life ya know? 270 degrees and no more than 7 minutes at a time. We dont burn or melt headlights in this house! I like to use small wood blocks on top of a cookie sheet. Very caliente, remove headlights with ove-gloves to work area which is your wife's nice tabletop LOL you can keep using ove gloves or just some thin work gloves to work on the capsule without burning your hands.

Step 3. Use special reverse expanding pliers EP-110 from expandingpliers.com $20 to carefully reverse ply starting from bottom of capsule. Always start at bottom because that way, if you damage something, it wont be very visible. Easy does it, slow and steady wins this race. Too fast and you will crack a bottom headlight lip area. Ask me how I know. :) These are relatively expensive headlights to crack, even if you did grab them at the pick and pull.

Step 4. Front plastics now removed. Tomorrow will clean up and share more on the "retrofit" plans.

Here's a pic of 5 headlamp capsules with the fronts baked off. LOL. These capsules are for donor parts to construct a perfect new unit. This way if you screw up while drilling or retrofitting new internal components, you arent out of luck!

I was lucky and at a junkyard, I found an SRX that had front end damage/crash repair and 2 nearly new aftermarket "DEPO" headlamps! I had them in the car for a while but because they were halogen, the HID projectors I put into them sat too far back in the housing mount, creating a large gap between the projector lense and the inner chrome housing. Lots of words to describe something that really triggered my "attention to detail" nerve. May seem obvious but for real, the Halogen capsules and the HID capsules are a different design. They look identical but trust me the internal plastic mounts to the lense mounts are different. Anyhow, I had to fix it!

So, as part of this project, I'll use the nice new front plastics only from those DEPO headlamps and use other "donor" D1S HID capsules as the proper HID mounting base. The end result should be that the assembly will look normal again... and brand new!

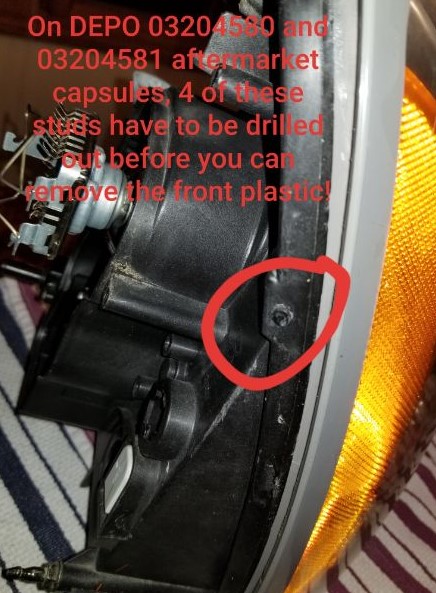

Interesting issue though. The DEPO units are not only glued together but also NAILED. Look at an example of these little friggin nails. I had to drill them out until they spun free, and yank them out with needle nose pliers. It wasn't until I removed 2 nails at bottom and 1 on each side, that I could bake these and remove the front plastic. Damn, this is a lot of work. I now understand why "pro retrofitters" get like $500 a headlamp for labor. Ugh.

Got busy at work, took a break from project, but now back w a bit of time to dedicate to reassembly.

Here is a video of the capsules coming together. The side markers have been blacked out, the vertical LED pipes installed and tested and the Whelen Vertex strobes are in. So cool.

Before you ask, I'm permitted for the strobes

Fogs have been retrofitted with 55w HID bulbs. Look at the ballast mounted inside of the fog/DRL capsule. There is room, provided it's a small ballast.

Here is a video showing everything reassembled. Note I went with LED bulbs for the orange DRL/turn signals. In order to pull this off, you need to use a resistor across the wire so the computer doesnt detect low resistance and do the rapid flash.

Look at the LED pipes. They are solid when the headlights are on, but they flash when headlights are off and the turn signal flashes. Kind of cool. I am still sorting out the wiring there. Big issues finding good connection for the LED switchback functionality.